The outer holes, along with the center vertical rib, allow for the attachment of bracing.Ĭan I cut the Plastic Column Form to a custom size? Whereas, the outer 2 hole pattern is sufficient for shorter pours-thus saving on labor. The inner 3 hole pattern allows for a tighter joint for higher pours (4 feet or more). There were several reasons for this concept. Why are there two sets of holes on the vertical flanges? These stresses and the severity of same can result in a detrimental effect upon the reusable life of the form. Higher liquid head, higher rates of pour, excess vibration, drilling of holes, and rough handling place greater stress on the form. The actual number of reuses of the PCF is dependent upon various jobsite conditions.

#CONCRETE FORMS TO GO AROUND COLUMNS FREE#

Deslauriers recommends a pour rate not to exceed 1200psf or an 8 foot liquid head at 70° F.Furthermore, standard practices limit concrete free fall to a max of 5 feet. The height is not the issue, but rather how fast should you pour.

The original PCF was limited to 1 foot high sections, but recent improvements in molding techniques has allowed the molding of an 8 foot high unit at greatly reduced costs. Thus, Deslauriers has several years of product history.

#CONCRETE FORMS TO GO AROUND COLUMNS FOR FREE#

Ready to sell your used heavy equipment or construction material? List your products today for free on Eiffel Trading’s online marketplace."When did Deslauriers decide to make the PCF?Īctually, the PCF (Plastic Column Form) has been on the market since 1993. Furthermore, our used material inventory includes used barrier wall, used HDPE pipe, and more.Īll of our listings are constantly being updated, but if you don’t see what you’re looking for, create a wanted listing for free. In addition to concrete formwork, Eiffel Trading’s inventory ranges to include shoring towers, pile driving machines, overhang buggies, and much more. When purchasing formwork for highway construction, factors such as the necessary dimensions and load bearing capabilities of finished concrete products should be taken into consideration.

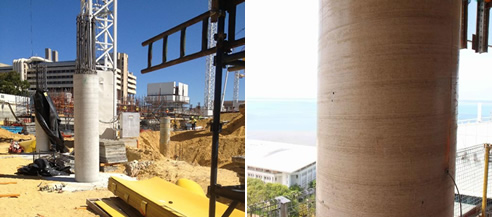

There’s quite a bit of overlap between the styles of formwork used for highway construction and bridge construction. Once concrete is cast, forms are removed and can be used for other highway projects or be used for bridge projects with similar needs. Most of the styles of formwork listed above are used temporarily. These are just some of the most popular styles of formwork used in highway construction. Plate girder formwork has the ability to create heavy-duty wall sections to support elevated girder bridges. Plate girder formwork is used to create girder bridge structures that belong to highway systems that involve elevated sections of highway. After which, it’s common for a collar of formwork to be clamped around column structures to support additional concrete beams as they are cast. When creating elevated highways, column formwork is frequently cast to the underside of concrete structures created with beam formwork.

Beam formwork typically comes in the shape of a three-sided box and can be applied in a variety of ways to create structures for elevated highways as well as other highway-related concrete shapes. Beam FormworkĪnytime beams are needed in highway construction, beam formwork is a go-to option. The end result is a long, continuous superstructure of connected modules. For long spans of elevated highway decks, deck formwork is frequently cast one module or section at a time. Deck formwork used to create highway structures is similar to the deck formwork used to create bridge structures. Column formwork, also sometimes referred to as pier formwork, comes in both spherical and rectangular designs (among other types of designs) to suit the various structural and aesthetic needs of highway projects.įor elevated areas of highway that require the creation of deck structures, deck formwork is often of great use. It’s an excellent choice for urban highway projects that necessitate highway structures above ground. This type of formwork is used to create concrete columns to support elevated highways. Below are five different concrete forms used in highway construction: 1. Various styles of formwork are well-suited to the creation of highways. There are numerous uses of formwork in highway construction, and timber, steel, aluminum, and plastic forms are all common in highway projects. It’s useful for paving long stretches of highway as well as building structures for elevated sections of highway systems. Since the 1950s, the popularity of formwork in highway construction has been on the rise.

0 kommentar(er)

0 kommentar(er)